The air flow meter, also known as the mass air flow (MAF) sensor, plays a crucial role in ensuring your car’s engine runs efficiently. This small but vital component measures the amount of air entering the engine and helps the engine control unit (ECU) adjust the fuel-to-air ratio for optimal combustion. When the air flow meter malfunctions, it can lead to poor performance, reduced fuel efficiency, and even engine stalling. Understanding how to diagnose, clean, and replace a faulty air flow meter can save you money and keep your car running smoothly.

What is an Air Flow Meter and Why is it Important?

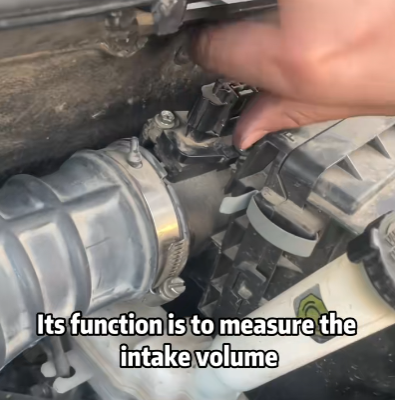

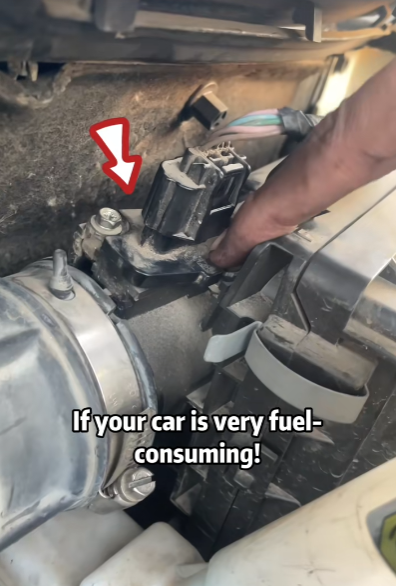

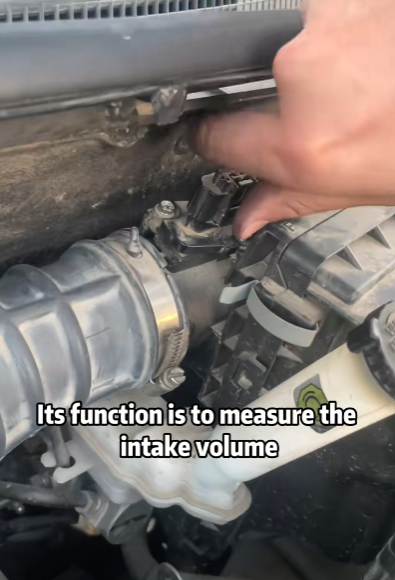

The air flow meter is a sensor located between the air filter and the throttle body. It measures the mass of air flowing into the engine, which allows the ECU to determine the correct amount of fuel to inject. This precise balance is necessary for optimal combustion, efficiency, and emission control.

There are two main types of air flow meters:

- Hot Wire MAF Sensor – Uses a heated wire to measure air flow based on temperature changes.

- Vane Meter (Older Models) – Uses a spring-loaded flap to measure airflow.

Modern vehicles predominantly use hot wire sensors due to their accuracy and reliability.

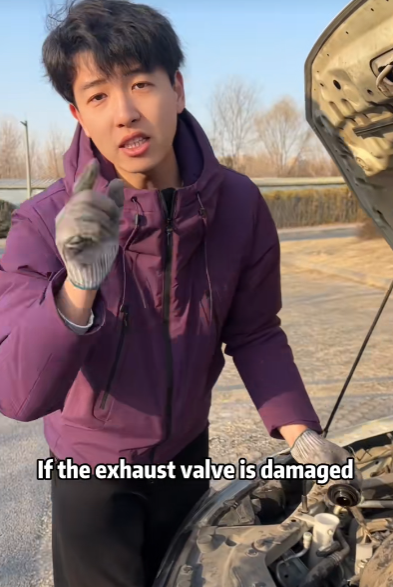

Symptoms of a Faulty Air Flow Meter

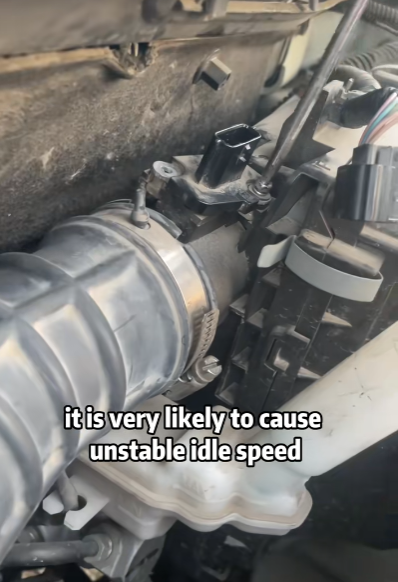

When the air flow meter starts to fail, it can cause various engine performance issues. Common symptoms include:

- Check Engine Light (CEL) Illuminated – A faulty sensor will often trigger a trouble code related to air-fuel mixture problems.

- Rough Idling – The engine may struggle to maintain a steady idle due to incorrect air intake readings.

- Reduced Fuel Efficiency – An incorrect fuel-to-air ratio can cause excessive fuel consumption.

- Loss of Power and Acceleration – The engine may hesitate or lag when you press the gas pedal.

- Black Smoke from Exhaust – A rich fuel mixture can cause unburnt fuel to exit through the exhaust.

- Stalling or Difficulty Starting – Severe sensor failure can prevent the engine from running properly.

If you experience these symptoms, diagnosing the air flow meter should be a priority.

Diagnosing a Faulty Air Flow Meter

To determine whether your air flow meter is the culprit, follow these steps:

Step 1: Scan for Trouble Codes

Use an OBD-II scanner to check for diagnostic trouble codes (DTCs). Common codes related to the MAF sensor include:

- P0100 – Mass or Volume Air Flow Circuit Malfunction

- P0101 – Mass Air Flow Sensor Out of Range

- P0102 – Mass Air Flow Sensor Low Input

- P0103 – Mass Air Flow Sensor High Input

- P0171/P0174 – Lean air-fuel mixture due to incorrect readings

Step 2: Perform a Visual Inspection

- Check for dirt or debris buildup on the sensor.

- Inspect the wiring and connectors for damage or corrosion.

- Ensure that the air intake hose is secure and free of leaks.

Step 3: Test the Sensor with a Multimeter

If you have a digital multimeter, you can test the voltage output of the MAF sensor to see if it fluctuates properly as the engine runs. Consult your vehicle’s service manual for the expected voltage range.

How to Clean the Air Flow Meter

Before replacing the air flow meter, try cleaning it. Dirt buildup on the sensor can cause incorrect readings and performance issues.

Tools and Materials Needed:

- MAF sensor cleaner (DO NOT use carburetor cleaner, as it can damage the sensor)

- Screwdriver or socket wrench (for sensor removal)

- Safety gloves and goggles

- Clean, lint-free cloth

Step-by-Step Replacement Process:

- Turn Off the Engine and Disconnect the Battery – This prevents electrical damage during installation.

- Remove the Faulty Sensor – Unscrew and detach the old sensor from the intake housing.

- Install the New Sensor – Ensure it is properly aligned before securing it in place.

- Reconnect Electrical Connectors – Ensure a secure and tight fit.

- Reconnect the Battery and Start the Engine – Let the engine run for a few minutes.

- Clear Any Diagnostic Trouble Codes (DTCs) – Use an OBD-II scanner to reset the check engine light.

- Test Drive the Vehicle – Check for improvements in acceleration, fuel efficiency, and idling.

Preventative Maintenance for Air Flow Meters

To extend the lifespan of your air flow meter and avoid frequent issues, follow these maintenance tips:

- Replace the Air Filter Regularly – A clean filter prevents dust and debris from contaminating the sensor.

- Inspect the Intake System for Leaks – Any unmetered air entering the system can cause incorrect readings.

- Use High-Quality Fuel – Poor-quality fuel can lead to excessive carbon buildup in the intake system.

- Periodically Clean the Sensor – Cleaning it every 15,000 to 30,000 miles can prevent sensor failure.

Conclusion

A faulty air flow meter can cause a range of engine performance issues, from rough idling to reduced fuel efficiency. Understanding how to diagnose, clean, and replace this component can save you money and prevent unexpected breakdowns. Regular maintenance, including air filter replacements and occasional sensor cleaning, will keep your vehicle running efficiently.

By taking a proactive approach to caring for your air flow meter, you ensure that your engine receives the proper air-fuel mixture, leading to better performance, lower emissions, and improved fuel economy. Whether you choose to clean or replace your air flow meter, following these steps will help keep your vehicle in top shape.